Optimizing Container Space with AI-Powered Strategies

04.13.2023

3D-bin packing is a common operation in warehousing and logistics, requiring the packing of a set of 3-dimensional items into larger containers. Inefficient bin packing strategies yield wasted container space, sponsoring negative economic impacts.

Wasteful bin-packing strategies impact both sides of the profit equation:

- Limiting the amount of revenue that can be realized from a fixed set of resources

- Increasing costs as more resources are needed to contain a fixed set of items

Production of performant bin-packing strategies is a worthy endeavor as organizations look to make better use of their available resources. Utilizing AI, efficient packing strategies can be automatically generated, enabling a reduction in wasted space and improved operational profitability.

The Impact of Wasteful Bin-Packing Strategies on Profitability

The bin-packing recommendations presented in this white paper are applicable to a diverse range of industries, including retail, e-commerce, food and beverage, healthcare, and transportation services such as airlines, trucking, or rail systems.

This use case highlights a national enterprise with transportation services that involve batches or smaller loads that do not require a full truck for transport. A considerable portion of the shipping provider’s business was derived from the provision of shipping services for a massive e-retailer. The primary responsibility was to transport goods from return-processing centers to distribution centers for restocking.

The business experienced difficulty making best use of available container space when loading products to ship. In an attempt to maximize space utilization, some standardized packing heuristics were implemented. An internal analysis of shipping manifests revealed an average of 30% of their shipped container volume was still going unutilized.

These inefficiencies placed a strain on the business, restricting the overall volume of product they could ship and ballooning their resource spend as supplementary containers were required to combat the packing inefficiencies. To solve for these inefficiencies, an efficient packing strategy to reduce wasted container space plaguing the operations is required.

Unpacking the Challenges: An Introduction to Bin Packing Strategies

3D-bin packing is a common, yet challenging, optimization problem that has drawn considerable attention from the applied and academic-research communities.

Not only is bin packing a task that humans struggle to perform effectively, the massive number of strategies that may be applied to any packing scenario make it a challenging task for traditional optimization methods. Because of this complexity, the business utilized several rules-of-thumb, i.e. heuristic methods. These methods did not satisfy the enterprise’s desire for waste reduction.

Additionally, many of the packages did not conform to standardized shipping dimensions, eliminating the opportunity to utilize blueprint-packing strategies.

This enterprise, along with the warehousing and logistics industry at large, stand to benefit from advanced tools to assist in the efficient packing of standardized and non-conforming items.

Innovative Solutions: AI-powered Bin Packing for Improved Resource Utilization

To address this challenging optimization problem, Object Computing’s team of engineers and data-scientists developed an application using Asterisms, a proprietary technology stack that includes a range of tools and platforms for building and deploying complex systems such as microservices architectures, cloud-native applications, and distributed systems.

The 3-D bin-packing application utilizes AI-powered genetic algorithms and LiDAR data, to generate efficient packing strategies for a set of known items and available containers.

Supplying item and container dimensions to a cloud storage manifest, the cloud-based packing optimizer can be run on request to determine item-by-item packing instructions that best utilize available container space.

- Algorithmic scalability: The optimization algorithm lends itself well to parallelization, allowing multiple processors to contribute to the packing of all containers. This useful feature leads to faster solutions and enables the solving of larger problems like scenarios with more items and containers.

- Multi-device capability: With cloud compute, multiple devices can add items to the packing manifest simultaneously. Incoming cargo can be assessed and registered by multiple individuals, reducing the overall lead time of manifest aggregation.

- Ease-of-use: The platform interface was made available as an iOS application, providing a single tool for operators to enter and verify item dimensions, visualize recommended packing strategies, and access detailed packing instructions. The iOS application discerns volumetric data via LiDAR-equipped devices. Dimensions of to-be-packed items canbe easily and accurately determined through devices like an iPad. Assessors do not need to manually enter complex geometries or measure package dimensions.

A Look Inside: How the AI-powered 3D Bin Packing Application Works

Fig. 1: Capturing Package Dimensions with the LiDAR Bin-Packing App

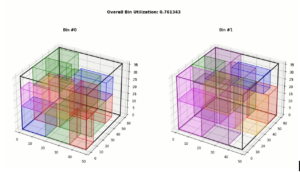

Fig. 2: Before Packing Optimization

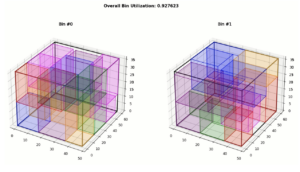

Fig. 3: After Packing Optimization

Employing the packing recommendations of the provided platform, the enterprise was able to substantially reduce their average wasted container volume, improving mean utilization from ~70% to over 90% in the two months following installation. Further, the business mitigated the time dedicated to ‘repacking’, a task previously conducted in an effort to improve the utilization achieved by initial live-packing attempts. These allowances have enabled an increase in shipping capacity and packing throughput, as well as a reduction in the number of supplementary containers required to meet service obligations.

Asterisms Ecosystem: Rapid and Effective Delivery of Sustainable Business Outcomes

Object Computing’s AI-powered bin packing optimization solution provides businesses across a wide range of industries with a compelling tool to improve operational efficiency, reduce waste, and increase profitability. The iOS application interface makes it easy for users to measure item dimensions, visualize recommended packing strategies, and access detailed packing instructions.

The Asterisms ecosystem offers the opportunity to achieve unprecedented levels of accuracy and speed in remote sensing-based monitoring and analysis, allowing for more effective and reliable decision-making.

With the Asterisms framework enabling the delivery of meaningful outcomes in weeks rather than months, businesses seeking to improve sustainability, efficiency, intelligence, and revenue can achieve their objectives rapidly and effectively.

BRING THE POSSIBILITIES INTO FOCUS

At Object Computing, we understand that every enterprise has unique challenges and requirements, which is why we work closely with our clients to customize our solutions to their specific needs. Our team of experienced engineers and data scientists can help you identify opportunities for improvement and develop strategies to achieve your goals.

Contact us today to learn more about how we can help your enterprise turn rich data insights into actionable, impactful outcomes.